Nā Paipu i Welded ʻia

Wehewehe Huahana

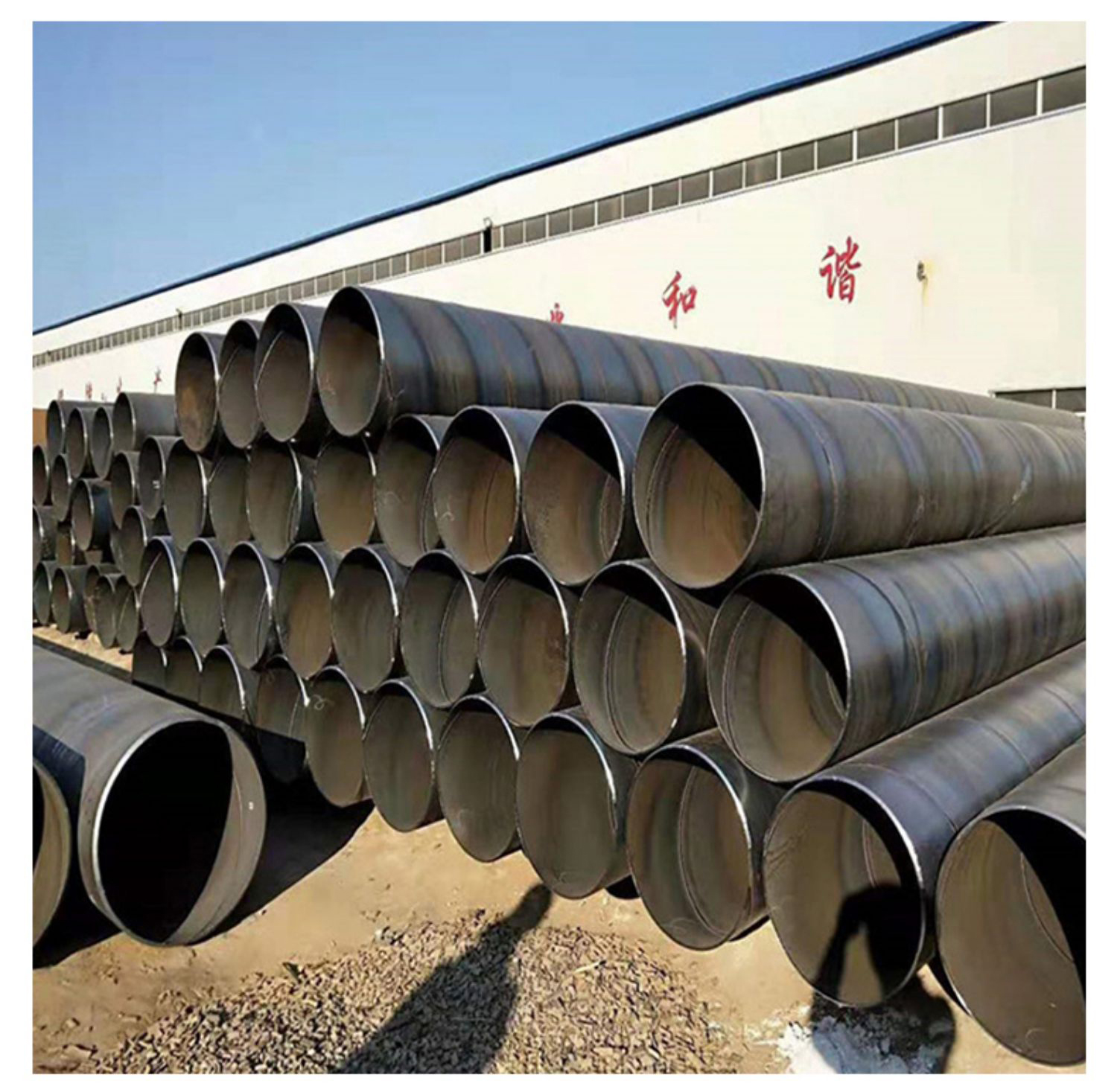

ʻO nā paipu i hoʻoheheʻe ʻia, i ʻike ʻia hoʻi he mau paipu kila i hoʻoheheʻe ʻia, hana ʻia ma ka ʻōwili ʻana i nā papa kila a i ʻole nā ʻāpana i loko o kahi ʻano tubular a laila hoʻoheheʻe i nā hui. Me nā paipu humuhumu ʻole, ʻo lākou kekahi o nā ʻano nui ʻelua o nā paipu kila. ʻO kā lākou mau hiʻohiʻona koʻikoʻi ka hana maʻalahi, ke kumukūʻai haʻahaʻa, a me nā ʻano kikoʻī like ʻole.

I. Ka Hoʻokaʻawale ʻana o ke Kumu: Ka Hoʻokaʻawale ʻana ma ke Kaʻina Hana Kuʻihao

Hoʻoholo nā kaʻina hana kuʻi like ʻole i ka hana o nā paipu i kuʻi ʻia. ʻEkolu mau ʻano nui:

• Paipu Welded Longitudinal (ERW): Ma hope o ka ʻōwili ʻana i ke kaula kila i loko o kahi ʻāpana poepoe a huinahā paha, ua wili ʻia kahi humuhumu ma ke ʻano lōʻihi (ka lōʻihi) ma ke ʻano o ka paipu. Hāʻawi kēia i ka pono hana kiʻekiʻe a me ke kumukūʻai haʻahaʻa, e kūpono ai no ka halihali wai haʻahaʻa haʻahaʻa (e like me ka wai a me ke kinoea) a me nā noi kākoʻo kūkulu. ʻO nā kikoʻī maʻamau e pili ana i nā anawaena liʻiliʻi a me waena (maʻamau ≤630mm).

• Paipu Welded Spiral (SSAW): Ua ʻōwili ʻia ke kaula kila ma ke kuhikuhi helical a ua wili ʻia ke kaula i ka manawa like, e hana ana i kahi wili wili. ʻOi aku ka like o ke kaumaha o ke kaula wili, e hāʻawi ana i ke kūpaʻa tensile a me ke kūlou maikaʻi loa i hoʻohālikelike ʻia me ka paipu wili wili pololei. ʻAe kēia i ka hana ʻana o nā paipu anawaena nui (a hiki i ka 3,000mm ke anawaena) a hoʻohana nui ʻia no ka halihali wai kiʻekiʻe (e like me nā paipu aila a me ke kinoea kūlohelohe) a me nā paipu hoʻokahe wai kūlanakauhale.

• Paipu kila kila i hoʻopaʻa ʻia: Hana ʻia mai ka pepa kila kila/ʻāpana, i hoʻopaʻa ʻia me ka hoʻohana ʻana i nā kaʻina hana e like me TIG (tungsten inert gas arc welding) a me MIG (metal metal arc welding). Loaʻa iā ia ke kūpaʻa i ka pala a me ke kūlana kiʻekiʻe o ke kila kila a kūpono ia no nā noi e pono ai nā mea kiʻekiʻe, e like me ka hana ʻana i ka meaʻai, nā kemika, a me nā mea lapaʻau. Hoʻohana pinepine ʻia ia i nā paipu pololei liʻiliʻi a me waena.

II. Nā Pōmaikaʻi Nui

1. Kumukūʻai Haʻahaʻa a me ka Hana Kiʻekiʻe: Ke hoʻohālikelike ʻia me ka paipu seamless (e pono ai nā kaʻina hana paʻakikī e like me ke kī ʻana a me ka ʻōwili ʻana), hāʻawi ka paipu welded i ka hoʻohana ʻana i nā mea maka kiʻekiʻe a me kahi kaʻina hana pōkole. ʻOi aku ka haʻahaʻa o nā kumukūʻai he 20%-50% no nā kikoʻī like. Eia kekahi, hiki ke hana ʻia ma nā ʻāpana a hoʻomau e hoʻokō i ke koi nui.

2. Nā Kikoʻī Kūlike: Hiki ke hana ʻia nā paipu me nā anawaena like ʻole (mai kekahi mau milimita a i kekahi mau mika), nā mānoanoa o ka paia, a me nā ʻāpana kea (poepoe, huinahā, a me ka huinahā) ma ke noi e hoʻokō i nā pono pilikino o nā noi like ʻole, me ke kūkulu ʻana a me ka ʻoihana.

3. Hana Maʻalahi: ʻO nā mea like a me nā wili paʻa e hoʻomaʻamaʻa i ka ʻoki ʻana, ka ʻeli ʻana, ke kūlou ʻana, a me nā hana hana ʻē aʻe, e hōʻoiaʻiʻo ana i ka hoʻonohonoho pono ʻana.

III. Nā Wahi Hoʻohana Nui

• ʻOihana Kūkulu: Hoʻohana ʻia i nā paipu hoʻolako wai a me nā paipu hoʻokahe wai, nā paipu pale ahi, nā kākoʻo kūkulu kila (e like me ke scaffolding a me nā stud pā pale), nā mōlina puka a me nā puka makani (nā paipu i hoʻopaʻa ʻia me nā huinahā), a pēlā aku.

• ʻĀpana ʻOihana: Hoʻohana ʻia ma ke ʻano he mau paipu lawe wai haʻahaʻa (wai, ea i hoʻopaʻa ʻia, mahu), nā paipu kākoʻo lako, nā pale hale hana, a pēlā aku; hoʻohana ʻia nā paipu wiliwili nui i hoʻopaʻa ʻia i nā paipu aila a me ke kinoea kūlohelohe mamao loa.

• ʻĀpana Kalana: Hoʻohana ʻia i loko o nā paipu hoʻokahe wai kūlanakauhale, nā pūnaewele paipu kinoea (kaomi waena a me ke kaomi haʻahaʻa), nā pou kukui alanui, nā pale kaʻa, a pēlā aku.

• Ke ola o kēlā me kēia lā: Hoʻohana ʻia nā paipu liʻiliʻi i hoʻopaʻa ʻia (e like me nā paipu kila kila) i loko o nā pale lako a me nā ʻauwai kīhini (e like me nā paipu hoʻopau o ka ʻahu ahi).

Hōʻike Huahana